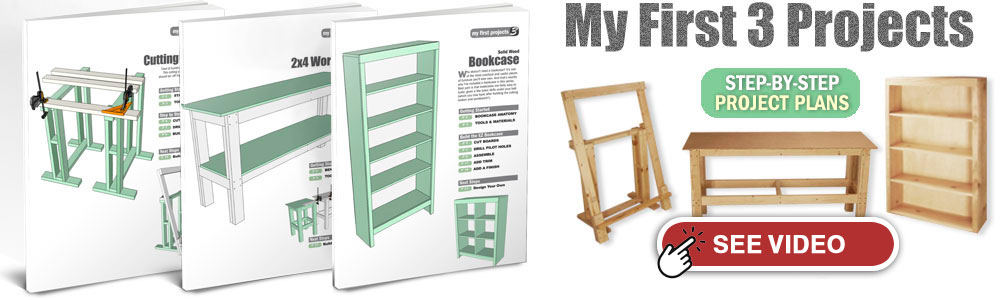

EZ Cutting Station |

EZ Workbench |

EZ Bookcase |

||||

Put your work where it should be—off the floor and within easy reach! This is a must-have item for anyone wanting to get started in building wood projects. Best part is that you'll learn all the basic construction skills needed for building more projects! Buy Individual Plan: $4.95 |

Unlike most workbench plans you'll find on the Web, my EZ Workbench lets you custom-design your bench in just about any size or shape you can imagine. That’s good news for those of us who have limited space to work in. Simple design uses 2x4s and plywood. Buy Individual Plan: $4.95 |

Who doesn't need a bookcase? Of course, that's the reason I decided to include this plan in my series My First Project. It's a perfect opportunity to put your basic building skills to work—and create a fantastic piece of furniture for your home or shop. Buy Individual Plan: $4.95 |